For further information download brochure or contact us!.

-

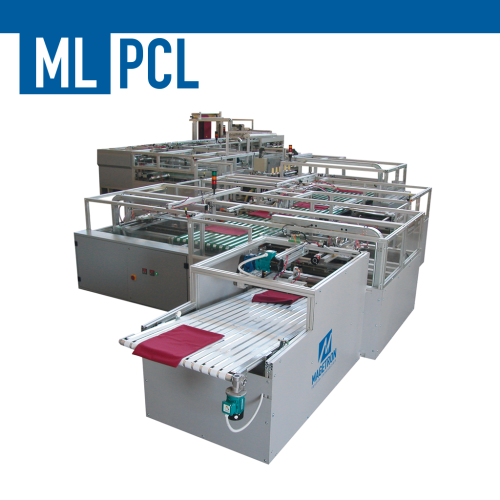

THREE SOLUTIONS, ONE TECHNOLOGY U-shaped (WxL): both sides length hemming & sewing, doubling (folding), cross cutting, label dispensing, sides closing (overlocking), stacking U-shaped (LxL): cross cutting, label dispensing, cross hemming & sewing, doubling (folding), side overlocking, stacking. L-shaped: right side length hemming & sewing, doubling (folding), cross cutting, label dispensing, cross and bottom overlocking, stacking. Automatic turning group can be connected with each machine. The Magetron ML-PCL takes over the complete processing procedure with extraordinary performance, uncompromising quality and flexibility. PRODUCTIVITY AND OUTSTANDING QUALITY Three complete lines for the making up of pillow cases grant the most complete choice in the production process. Each line is realized in order to maximize and optimize productivity and efficiency. REAL AUTOMATION From the roll to a perfect quality of the final product. Thanks to technological development, to engineering and to innovative solutions, it is possible to produce pillow cases with an extraordinary level of quality. MULTIPURPOSE SOLUTION Depending on the configuration this machine can be used for producing even cushion and pillow ticks providing an high level of versatility and flexibility.FULLY AUTOMATIC FINISHING OF BLANKETS AND BEDSPREADS Longitudinal section: fabric guiding, banding/hemming, sewing. Cross cutting section: dimensioning, cross cutting, edge trimming, stacking. Cross sewing section: label dispensing, banding/hemming, sewing This installation takes over the complete processing procedure with extraordinary performance, uncompromising quality and flexibility. MODULAR CONCEPT Longitudinal and cross sections can be connected in one complete fully automatic line or used separately. Each module can complete a part of the process giving total versatility and flexibility. QUALITY Innovative technology, optimal processing methods and superior standards of construction grant an incredibly high level of the final output. EFFICIENCY AND PRODUCTIVITY Extraordinary efficiency, high productivity, attractive cost-performance ratio, profitability on daily basis.

For further information download brochure or contact us!.

The Magetron M600 can manufacture fitted sheets (box making), delivering an outstanding quality and high performance of the process. This installation can complete the following processes:- Unrolling the fabric webs

- Edge cutting of the product

- Cross cutting

- Corner formation

- Label insertion (optional)

- Sewing (overlocking) of the corners

For further information download brochure or contact us!.

Fully automatic finishing of duvet covers made of two fabric webs. The Magetron Ml-DL can manufacture with high performance and excellent quality different kind of duvet covers, depending on the requirements of the customers. The process consist of:- Length hemming & sewing of the first fabric layer

- Length hemming & sewing of the second fabric layer

- Perfect superimposition of the two fabric webs

- Bottom side closing (overlocking)

- Cross cutting

- Label dispensing

- Sides closing (overlocking)

- Stacking

For further information download brochure or contact us!.

Semi-automatic solution for side overlocking stitching of pillow cases and cushion cover with automatic label insertion. High productivity, perfect stitching quality and constant width dimensioning of the final product are some of the advantages of this machine. The right solution to upgrade manual stitching to an efficient process.For further information download brochure or contact us!.

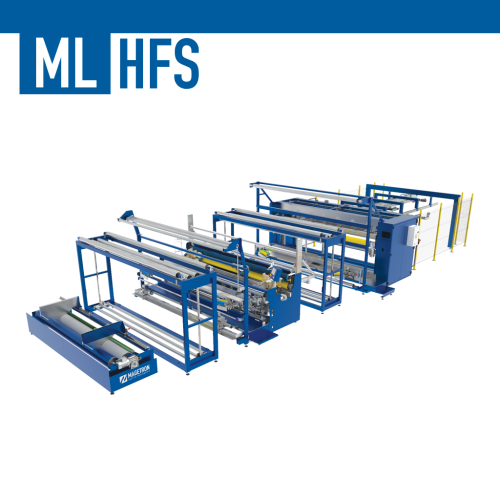

Fabric guiding, edge trimming, label dispensing, hemming, sewing. The longitudinal hemming & cross cutting ML-HFS machine can successfully complete all lengthwise processing procedures with an incredibly high level of quality. The machine can be used stand alone or connected with automatic cross cutting. The modular design grants flexibility and allows to split the investment depending on customers requirements. The highest technology systems allow to minimizing the intervention of the operator providing high quality standard of the output. The engineering and industrial development, the construction quality of the mechanic and technologic materials allow having an high reliable installation which grants a constant production on daily basis.For further information download brochure or contact us!.

The perfect solution for turning duvet covers by means of vacuum air and having corners perfectly out. High productivity and fast payback are the main advantage of this solution. Minimize WIP and avoid duvet covers laying around your factory floor. The right solution for a clean environment, organized end efficient workflow and for improving operators comfort.For further information download brochure or contact us!.

The Duvet Cover - 3 sides closing is the perfect solution for completing the process of sewing (overlocking) in the duvet cover manufacturing. The machine provides the sewing of the 3 sides of the duvet covers (it's possible also to stitch also 2 sides with the same machine). The result is precision in the duvet cover dimensions and perfect sewing quality. It's also possible to stitch the labels in accordance with customer's requirement. All the process is automated and there is minimum intervention from operator side. This grant simple and efficient workflow in the process. The machine moreover grant flexibility and versatility in the product dimension: the machine is adjustable in the product width covering all customer and market requirement. The perfect solution for those who need a machine with different concept compared with the fully integrated duvet cover line.For further information download brochure or contact us!.

The Duvet Cover - 2 sides closing is the perfect solution for completing the process of sewing (overlocking) in the duvet cover manufacturing. The machine provides the sewing of the sides of the duvet covers. The result is precision in the duvet cover dimensions and perfect sewing quality. It's also possible to stitch the labels in accordance with customer's requirement. All the process is automated and there is minimum intervention from operator side. This grant simple and efficient workflow in the process. The machine moreover grant flexibility and versatility in the product dimension: the machine is adjustable in the product width covering all customer and market requirement. The perfect solution for those who need a machine with different concept compared with the fully integrated duvet cover line.For further information download brochure or contact us!.

Fully automatic finishing of bed sheets. Longitudinal hemming and sewing, dimensioning, cross cutting, edge trimming, label dispensing, cross hemming and sewing, stacking. The Magetron ML-FFS takes over the complete processing procedure with an extraordinary performance, uncompromising quality and flexibility. EFFICIENCY AND PRODUCTIVITY Extraordinary efficiency, high productivity, attractive cost-performance ratio and profitability on a daily basis are the main advantages of this equipment. QUALITY AND FLEXIBILITY Innovative technology, optimal processing methods and superior standards of construction grant an incredibly high level of the final output. Capable to process different kind of home textiles and uncountable options available in Magetron ML-FFS can grant high standards of flexibility and customization, key factor in the nowadays' success. MODULAR CONCEPT Longitudinal sewing and cross cutting cross hemming can be connected in one complete fully automatic line or used separately. Each module can complete a part of the process giving, in this way, total versatility and flexibility.For further information download brochure or contact us!.

The panel cutter machine is used for cutting panels directly from fabric rolls. The process consists of: edge guiding, length cutting (optional), dimensioning, cross cutting and stacking. All home textile flexible materials (flat sheets, fitted sheets, duvet cover, table cloths, curtains and so on) can be efficiently cut, stacked and further processed with an incredibly high level of accuracy using M700 panel cutter machine. Also technical textile, non-woven materials and laminates can be processed in this machine. UNCOMPROMISING PERFORMANCE AND QUALITY Unprecedented productivity, quality, and precision in cutting system. This is the result of a perfect symbiosis between intelligent control technology and precision engineering. The low operating cost and simple integration in existing production workflows further contribute to an extraordinary quick ROI. PRECISION BY DESIGN The perfect accuracy in product dimensioning and stacking optimize the working and process flows. HIGH TECHNOLOGY ON SOLID GROUND Project development, production and assembling are all made in Italy inside our factory. This grants an high reliability level which is supported by an efficient after sales service as well as on-line assistance.For further information download brochure or contact us!.

This site uses cookies and third-party technicians . In no way we are used cookie profiling .

Continuing the voyage, without making any changes to your settings , you confirm that you want to accept all cookies used by our site . For more information please read " the section dedicated to the management of cookies " .

Continue More information